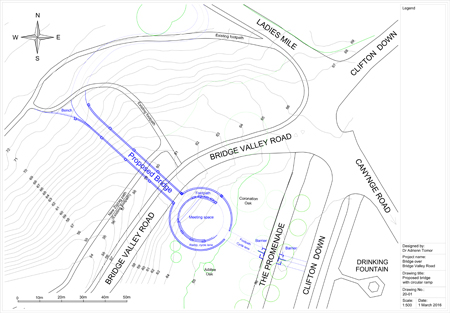

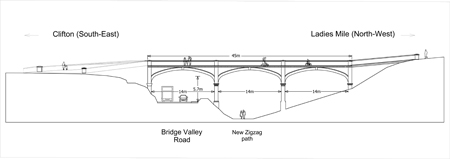

On 13 July 2016 the planning committee of Bristol City Council granted permission for a 50m-long, three-span stone arch bridge to provide safe crossing for pedestrians and cyclists across a busy road separating the Downs, the largest green space in Bristol, England.

The new bridge is expected to last for over 300 years and will require minimum maintenance.

The choice for a stone arch bridge design was selected to complement the 19th century grand classical architecture in the surrounding Clifton conservation area, which is home to another bridge of note, the Clifton Suspension Bridge. The community-initiated project has also been designed to offer unique opportunities for relearning the art of building masonry bridges, create local income generation and involve arts and heritage groups.

The programme is remarkable because, if it bears fruit, it will lead to the first multi-span stone bridge constructed in Europe over the past 100 years. The bridge designer, Dr Adrienn Tomor of the University of the West of England, believes the project represents a new era for masonry arch bridge construction in the UK and beyond, and she hopes to demonstrate that masonry bridges are still feasible for the 21st century: “While new bridges are designed for 120 years in the UK, most masonry bridges in the transport network are over 150 years old and still carry traffic without any change in their original form. There are also a number of bridges still in use that were built by the Romans about 2,000 years old. Clearly we have a lot to learn from our predecessors.”

For the design, alternative bridge types and building technologies were considered including a steel bridge and prefabricated or ‘flat-pack’ arches. However, apart from complementing the architectural style in the conservation area, the selected option also needed a sufficient element of novelty to enable funding to be raised. Dr Tomor explains: “We have had no funding available. All the design and consultation work have been done entirely on a voluntary basis with the local group Friends of the Downs and Avon Gorge and we will have to raise all the funds for the construction. I believe that solid stone arch bridge is the right architectural solution for the location and will provide sufficient novelty to realise the project.”

The cost of the proposed stone bridge is estimated to be around US$2.8 million, a cost comparable to a steel bridge at the location but one that will require less maintenance during its life: “Despite the expected high construction costs, the cost of masonry arch bridges appears to be similar to that of concrete or steel bridges. This is largely down to the lack of need for expensive machinery or equipment. Masonry bridges have always been built with predominantly manual labour and with relatively simple lifting equipment. The life-cycle maintenance costs for masonry bridges are far lower than for other bridges and, if maintained properly, they can well outlast any other bridge type.” The project is expected to provide a large-scale feasibility case study for costs, construction techniques and sustainability from environmental, economic and social perspectives.

For Tomor, who has spent her academic life studying masonry arch bridges and has been volunteering her structural engineering skills to the project for the last four years, the project is a dream come true: “Everything seems to be falling into place. At UWE we have been looking into the long-term performance, condition monitoring, environmental impact and maintenance needs for masonry arch bridges and are also running dedicated bridge inspection courses for the new bridge inspection certification scheme for the industry. That the evidence is increasingly pointing towards the unique feasibility and long-term sustainability of masonry bridges is hard to ignore.”

A main challenge for the project is that there is no living, practical experience in this type of construction in Europe. The project team will need to rely on historical accounts from before the early 1900s but may also be able to engage with expertise from China where these bridges are still being built. “We will need to understand the traditional building processes but make use of modern technology wherever appropriate, for example for stone cutting, transport and lifting. One of the many interesting aspects of the project is the scaffolding. Load-bearing scaffolding for masonry bridges is an art and skill in itself, often depicted in historical paintings and drawings. We could use a combination of modern and traditional scaffolding methods and engage with local boat builders in Bristol, as the scaffolding is not dissimilar to an upside-down boat. We will have to see what works best for the project.”

The construction of the bridge is expected to take around a year and require full or partial closure of Bridge Valley Road. “I am sure that keeping the road open for the entire construction would be possible, but it would put so much constraint on the project that I don’t think would be worthwhile - not being on a primary road network,” says Tomor. “Being the first large arch bridge to be built for about 100 years we need to first focus on getting the basics right. Once we have a reasonable understanding of the construction process we can try exploring other challenges. I am hopeful that this will not be the only such bridge to be built in the foreseeable future.”

The construction will provide a number of educational opportunities for apprentices, university students, disability and community groups as well as colleges, including those offering stonemasonry courses such as Bath College.

Through the project Tomor hopes to investigate the potential for offering an additional option to contemporary bridge design practices. “Naturally, masonry bridges will not be suitable for everywhere, neither are other bridge types. They may be suitable solutions for small spans or multi-span bridges and where life-cycle maintenance costs, long-term sustainability, aesthetics and quality are of significant importance.”

It helps that Bristol City Council staff has been positive during the consultation process, says Tomor: “It was interesting because although I expected a lot of opposition from the local highways department, the engineers had no objections for a stone arch bridge and were aware that these high-quality structures will pose them little maintenance issues. It is mostly low quality steel and concrete bridges that cause the majority of maintenance problems and expense for bridge owners.”

The next step for the project is to raise the US$2.8 million necessary to turn the dream into reality. While the project team is finalising the planning conditions with Bristol City Council it will also be setting up a charity organisation that will begin the fundraising. The construction will be conducted through the charity to maximise the learning and community involvement opportunities.

The initiative is not only about building a bridge in Bristol, but also about creating a new vision that will offer inspiration for generations to come.

To find out more about the project visit https://bridgevalleyroad.wordpress.com/