The damage is unlikely to be detected using standard visual inspections, the researchers from Washington State Univerity and Montana State University found. Some of the samples that had significant degradation within the concrete had been rated as good or satisfactory in bridge inspections.

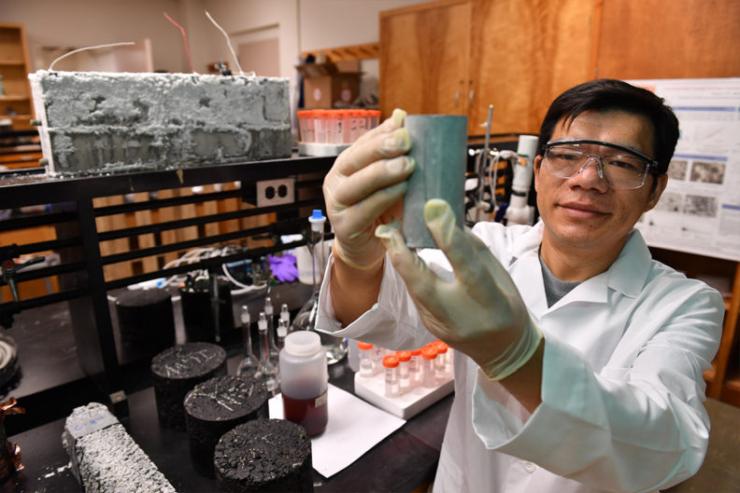

The project’s leader compared the chemical’s invisible degradation and concrete softening to what happens with ageing osteoporotic bones. “With rock salt, you can see there’s a problem, due to visible symptoms such as scaling and spalling;” said Xianming Shi, associate professor in Washington State University’s department of civil and environmental engineering. “In the case of the magnesium chloride, however, when you can see something, it might be too late to fix.”

Samples of concrete exposed to magnesium chloride in the laboratory with repeated freeze-and-thaw cycles lost more strength than samples exposed to rock salt, even though they showed no visual signs of damage.

The work was funded by the US and Oregon departments of transportation as well as by the National Natural Science Foundation of China.

Transportation officials in the US began using magnesium chloride about 20 years ago. Like rock salt, magnesium chloride prevents ice formation on roadways. It works well, particularly, in extremely cold temperatures when rock salt stops working. Magnesium chloride also is thought to be a more environmentally friendly alternative to rock salt.

About 20 US states affected by cold weather use magnesium chloride for snow and ice control, sometimes in combination with other treatments or, in a few cases, as the only treatment. In recent decades, the new treatments, including the use of magnesium chloride, have led to improved driving conditions on winter roads, the researchers said.

At the same time, researchers have known that many types of road salts - including magnesium chloride - degrade concrete, causing both physical and chemical deterioration. But they lacked a clear understanding of the microscopic changes in the concrete.

The study allowed the researchers to unravel how nano-sized crystals form within concrete samples. The formation of these crystals resulted in stress build-up and calcium leaching in the concrete, both of which significantly reduced its strength.

They also found that none of the magnesium chloride samples showed any typical visible distress even after 10 accelerated cycles of freezing and thawing.

In addition to the laboratory observations, the researchers tested sample cores from about 10 Oregon bridge decks that had been treated annually with magnesium chloride. They discovered a significant compromise in splitting tensile strength - a property that affects cracking resistance and load-bearing capacity - of as much as 50%. They also saw an up to 60% reduction in the concrete’s micro-hardness. The worst effects often occurred about 12mm to 25mm inside the sample, rather than on the concrete surface.