The team set out to tackle the deterioration caused by the salt spread on roads and pavements to stop them freezing.

The new concrete mix is described as absorbing 64% less water and 90% less salt than normal concrete, whilst being up to 42% stronger.

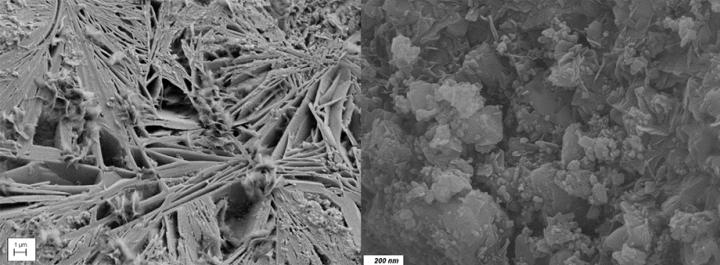

“Incorporation of a sodium acetate compound into concrete, at the mixing stage, works on absorbing some of the water to form crystals that line the walls of the pores in the concrete,” said Mazen Al-Kheetan, a PhD student at Brunel’s department of civil and environmental engineering, who is leading the project. “These crystals increase the hydrophobicity of the concrete – the amount concrete repels the water – which ensures the reduction of water uptake through the pores.

“Also, when applying de-icing salt to pavements made from this concrete mix, the presence of the protective compound within the pores work on fending off both the water and the waterborne chlorides.”

(Left) Sodium acetate at x10000 zoom; (Right) sodium acetate interacting with concrete at x20000 zoom.

Al-Kheetan said that, whilst the long-term performance of the material is being evaluated, the research team is confident that new mix can offer substantial economic advantages over currently available alternatives as it is cheap and easy to prepare. The researchers are also confident that the better protection from salt damage is not at the expense of performance in other areas.

“In our initial experimental work, we noticed that using the sodium acetate compound might reduce the compressive strength of concrete, despite its advantage in reducing the water absorption of concrete,” said Al-Kheetan. “Accordingly, we have worked on producing an optimum formulation of concrete with optimum compound dose to achieve maximum protection and preserved strength.

“Interestingly, we managed to produce concrete with the incorporated compound that has 64% less permeability than normal concrete and reduces chloride ingress by more than 90%. Meanwhile, when it came to the compressive strength of concrete, a maximum strength gain of 42% was achieved.”

The work is published in a research paper, Integration of anhydrous sodium acetate (ASAc) into concrete pavement for protection against harmful impact of deicing salt, in the Journal of the Minerals, Metals & Materials Society.