The proposed bridge would have been the world’s longest at the time.

The MIT team explained that in 1502, Sultan Bayezid II sent out the Renaissance equivalent of a government request for proposals, seeking a design for a bridge to connect Istanbul with its neighbouring city, Galata. Leonardo da Vinci - already a well-known artist and inventor - came up with a novel bridge design that he described in a letter to the Sultan and sketched in a small drawing in his notebook.

He didn’t get the job. But 500 years after his death, the design for what would have been the world’s longest bridge span of its time intrigued researchers at MIT, who wondered how thought-through Leonardo’s concept was and whether it really would have worked.

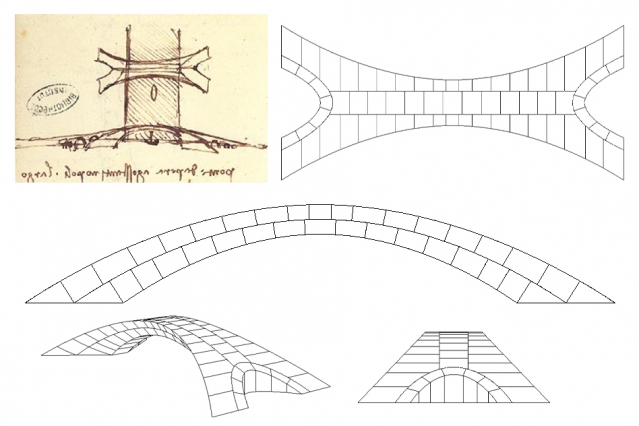

Above: Leonardo da Vinci’s original drawing of the bridge proposal (top left), showing a bird's eye view at top and a side view below, including a sailing boat passing under the bridge. To the right and below are drawings by Karly Bast and Michelle Xie showing how the structure could be divided up into 126 individual blocks, which were 3D printed to build a scale model.

Recent graduate student Karly Bast working with professor of architecture and of civil and environmental engineering John Ochsendorf and undergraduate Michelle Xie to tackle the problem. They analysed the available documents, the possible materials and construction methods that were available at the time, and the geological conditions at the proposed site, the Golden Horn river estuary.

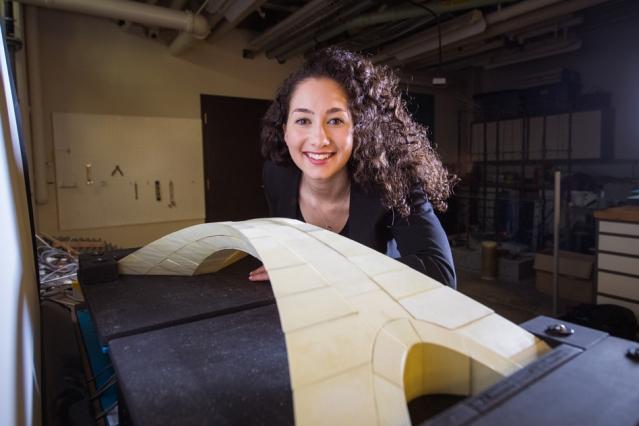

The team then built a detailed scale model to test the structure’s ability to stand and support weight, and even to withstand settlement of its foundations.

Above: Recent graduate student Karly Bast shows off the scale model that she and her co-workers used to prove the design’s feasibility. (Image: Gretchen Ertl)

The results of the study were presented in Barcelona last week at the conference of the International Association for Shell & Spatial Structures. They will also be featured in a talk in Cambridge, Massachusetts, later this month and in an episode of the PBS television programme Nova, set to air in the USA on 13 November.

In Leonardo’s time, most masonry bridge supports were made in the form of conventional semi-circular arches, which would have required 10 or more piers along the span to support such a long bridge. Leonardo’s bridge concept was dramatically different — a flattened arch that would be tall enough to allow a sailing boat to pass underneath with its mast in place, but that would cross the wide span with a single enormous arch.

The bridge would have been about 280m, making it the longest span in the world at that time, had it been built. “It’s incredibly ambitious,” said Bast. “It was about 10 times longer than typical bridges of that time.”

The design also featured an unusual way of stabilising the span against lateral. Leonardo proposed abutments that splayed outward on either side.

In his notebooks and letter to the Sultan, Leonardo provided no details about the materials that would be used or the method of construction. Bast and the team analyzed the materials available at the time and concluded that the bridge could only have been made of stone, because wood or brick could not have carried the loads of such a long span. And they concluded that, as in classical masonry bridges such as those built by the Romans, the bridge would stand on its own under the force of gravity, without any fasteners or mortar to hold the stone together.

To prove that, they had to build a model and demonstrate its stability. They decided on a design with 126 blocks for their model, which was built at a scale of 1 to 500. Then the individual blocks were made on a 3D printer, taking about six hours per block to produce.

“It was time-consuming, but 3D printing allowed us to accurately recreate this very complex geometry,” said Bast.

MIT pointed out that this is not the first attempt to reproduce Leonardo’s basic bridge design in physical form. Others, including a pedestrian bridge in Norway, have been inspired by his design, but in that case modern materials — steel and concrete — were used.

“That was not a test to see if his design would work with the technology from his time,” said Bast. But because of the nature of gravity-supported masonry, the faithful scale model, albeit made of a different material, would provide such a test.

“It’s all held together by compression only,” she said. “We wanted to really show that the forces are all being transferred within the structure,” which is key to ensuring that the bridge would stand solidly and not topple.

As with actual masonry arch bridge construction, the 'stones' were supported by a scaffolding structure as they were assembled, and only after they were all in place could the scaffolding be removed to allow the structure to support itself. Then it came time to insert the final piece in the structure, the keystone at the very top of the arch.

“When we put it in, we had to squeeze it in. That was the critical moment when we first put the bridge together. I had a lot of doubts” as to whether it would all work, Bast recalled. But “when I put the keystone in, I thought, ‘this is going to work’. And after that, we took the scaffolding out, and it stood up.”