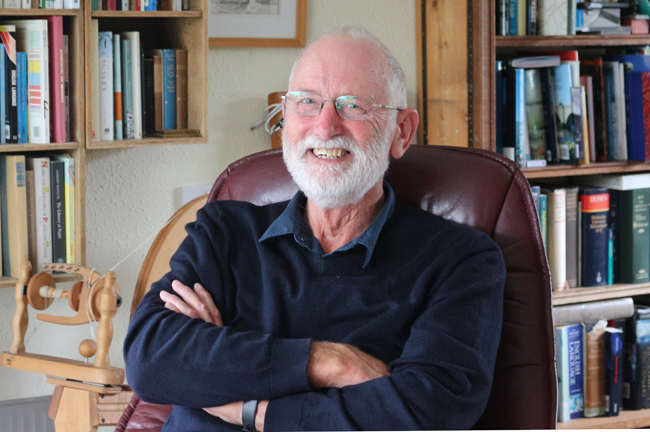

I am in Bill Harvey’s home in the city of Exeter in south-west England and he is hanging out the washing in his wilded garden in the hope to beat the next rain shower. A bum bag around his waist contains a plastic oval with a tube that is drip feeding chemotherapy into his body. The treatment has seriously affected his life over the course of the last year, he says, with unpredictable strength levels making it difficult to make firm plans. By all accounts though, it appears only to have slowed him down to a level that would be described as ‘full tilt’ by normal human standards.

The illness certainly did not prevent him co-hosting a workshop on arch structures at Bridges 2021, an event during which he was awarded the Bridge Owners Forum’s Bridges Lifetime Award. It did slow him down a bit, he admits, during a recently completed 482km-long bike ride for charity Cancer Research UK, for which he raised over US$7,000. The amount was a pleasant surprise to him, because he had set himself a target of US$480, fully expecting to make up any shortfall himself. I suspect that it wasn’t such a big a surprise to the many students and fellow members of the bridge community that have come into contact with his sharp mind and warm humour over an eventful career. Over the course of three hours, in an interview regularly punctuated by bursts of laughter, he tells me about his life and work on bridges.

Bill Harvey was born in the town of Doncaster, South Yorkshire, in north England in 1947. His father was what he describes as a ‘numbers’ man’ whose job at Briggs Motors was to estimate the cost of building cars. His mother left school at 13 and was an apprentice in a dairy until she became involved in the aerospace sector at Doncaster aerodrome. Pivotal in Bill’s life direction was his maternal grandfather, Ezra Spink, a man he regarded as a hero and who, despite a hard life, was always cheerful. “Seeing a hard life like that is important. Not enough people see what life can do to you.”

In spite of no connections to civil engineering, by the age of seven a young Bill already knew what he wanted to do: build bridges. “My grandmother’s family lived in Bristol so we went there on all our summer holidays. My uncle took me to see the Clifton Suspension Bridge and, after that, whenever anyone asked me what I would do when grown up I would say, ‘I’m going to build bridges’.” When the news was presented to his grandfather, he remarked, “You are going to university and be a civil engineer. You. Are. Not. Going. To. Dirty. Your. Hands.” “I never wavered from my intention,” says Bill, “and I think that is the first big stroke of luck in general life, knowing what I wanted to do right through. And 67 years on I still don’t regret it.”

At the age of 12, Bill and his family moved to Billericay in Essex, where his father had found new employment in the automotive industry. Later, as an undergraduate at Leeds University, he fell under the influence of Professor Evans, to whom he attributes his ability for being at ease with ‘the bosses’, and speaking his mind. “Professor Evans talked to us as people, treated us as people, and we got used to that. He was 67, an old man, but he was a serious power in the land.”

Overseeing a large-scale testing lab that carried out much engineering forensic work, Evans had an ear for structural collapses. “I have this vivid image of him storming out of the office and shouting, ‘Ferrybridge cooling towers have come down. First three get in the car!’ By then, there were seven people standing outside his car. He knew it would be interesting, and he would grab three students and off he went.”

Bill’s entry into civil engineering was a training scheme run by Leeds City Council, in what he calls “the days engineering was carried out in-house”, when city civil engineers had more influence in local authorities than today. Much construction was taking place in the city, “So you did eight months on roads, eight months on drainage and eight months on bridges.”

During this time, he was fascinated by the impact that civil engineering had on the successful functioning of a city, “Knostrop [formerly Knowsthorpe] Sewage Works was grossly overwhelmed. They deliberately put the design office in the sewage works, so people were aware of what was going on. When I arrived, the boss of the office said, ‘If it starts raining, put on your coat and wait at the front door. I’ll fetch you.’ He took me to a pit in the ground that was around 10m2, 6m deep, with a big wooden trench across the middle of it. The pit opened and there were these two enormous tunnels going out on one side of it. And all this sewage was going across this wooden trench into the sewage works. We stayed there for ten minutes until suddenly the whole pit was full, and the tunnels then started running full bore straight into the river. ‘That is what we have to stop,’ said the boss. ‘Go and carry on with your work’,” laughs Bill.

At the end of his two-year stint at Leeds City Council, Bill decided to move on: He hadn’t enjoyed his time at the bridge office, where the status quo did not welcome trainees questioning bridge element design and calculations that had come from further up the chain, in stark contrast to the Professor Evans approach.

The Humber Bridge was the first - and nearly the final - bridge construction project that Bill worked on (Shutterstock)

A speculative letter to Freeman Fox & Partners with a request to work on the most exciting project in the country at the time – the construction of the record-breaking 2.2km-long Humber Bridge – succeeded, and he was soon working on the re-enforced concrete anchorage at the north end of the crossing. There he found himself carrying out calculations that the contractor should have done, but couldn’t, using seven-figure log tables. “It took me a week to work out the maths and another week to process the numbers. I wrote it all out nicely on bits of paper and my equivalent across the river came and asked if he could borrow them. When I eventually got the notes back they were all wrinkled. I later heard the story that he’d let them blow away half way across the river and spent an hour in the river looking for them and trying to pick them up!”

His ability to be at ease in the company of senior management was spotted, and he was given the unofficial duties of entertaining the ‘London people’ that arrived by train to the meetings at the main office on the other side of the Humber. “Very often the tide was out, and I would be sent there to prevent them from crawling all over our site. So I spent the odd hour sat in Ralph Freeman’s Rolls, chatting with him on the shores of the Humber.”

Although a highly educational experience, Bill hankered for a more hands-on role than that of engineering overseer, and in 1975 he started work for Redpath Dorman Long, the contractor for a new crossing 50km away from the Humber Bridge, the Ouse Bridge.

“It was much more interesting, actually doing the work and managing a chunk of the site, working with the foreman and joiners. It was a joy, just my idea of fun.” The fun turned slightly sour when the section foreman developed health problems, and Bill added his responsibilities to his role. “I was left trying to do both jobs, working out where the [150] men should be, what they should be doing, making sure they had everything they needed, the tools, equipment and materials, week by week and day by day. The hardest thing of all was banging on the cabin wall when the rain stopped. ‘Come on guys, time to start’.”

After a number of projects, by some roundabout quirk of fate, Bill eventually found himself back on the Humber Bridge in March 1977 as a contractor, preparing the installation of the suspension cables. His return nearly resulted in a fatal tragedy with him in the starring role.

Bill remembers how the night after the long catwalk had been completed also happened to present ideal temperature and weather conditions for the installation of the first wire. At 1:00am, he was on his own in the middle of the Barton Viaduct side span, where the last of the catwalk mesh sections had been installed. Armed with a radio and levelling staff with a torch at its end, which was being observed at a distance to work out the correct sag of the wire, the work was completed and he set off on his journey back. “As I set off walking I just stepped into a hole…

“When they had put down the last 30m of mesh down, they didn’t fasten the two ends together. And in the night [gesturing hands pulling apart] they had gone back just enough for me to step into the gap, 500 feet over the river. It must have been less than a meter wide. When I got back to my feet, I still had all my gear!” he laughs.

Aberfeldy Bridge, Scotland was Bill's first masonry arch assessment (Shutterstock)

Eventually, home life (two children) demanded stability and Bill started a long career in education that began at the University of Dundee in Scotland and ended at the University of Exeter in south-west England some 25 years later. It was at Dundee that he met David Smith, ex-chief engineer at Mott MacDonald, who suggested to Bill that he might want to look into masonry arch bridges. “He said that no one had done anything on them for a long time.” So Bill did, and, months later, he and colleague Fraser Smith were in Aberfeldy, Scotland, carrying out an assessment on a 250-year-old bridge near the site of a new barytes mine, whose heavy lead ore was in great demand as a weighting agent for drilling fluids in oil and gas exploration. “In those days it was MEXE method that everyone used, but around that time Jacques Heyman published a couple of papers on plastic theorems, showing how they could be applied to masonry.” The bridge in Aberfeldy marked the start of a lifelong fascination with how masonry arch bridges work. “There was so much that was clearly wrong, and so much to learn about interaction.” With Fraser Smith as his assistant, and using the first ‘proper PC’ in the university, Bill developed new software that could help engineers use new concepts in mechanical analysis that had been developed by Heyman.

Archie M is different to other tools, says Bill, because it enables users to ask questions of a structure’s design: whether the ring of the arch is as it appears, whether it would make a difference if it wasn’t as it appears. “So the question becomes, ‘What do you need?’ It is not a question of how much load this bridge will carry, it’s more of a question of how much arch you need to carry this load.”

Archie M was not originally conceived for commercial use but, when word got around, Bill was flown to Belfast to talk to a senior civil engineer at the Northern Ireland Department of the Environment. “He said, ‘Do you see all these reports up here? Every one of them condemns a bridge, and we can’t afford to close the bridge. So they haven’t gone into files, they just sit there and scare me to death. I need a tool that lets me decide if I’m ok or not.’” Said engineer became the first customer of Archie M, and nearly 40 years later Bill still receives a regular stream of Archie M-related emails from users on a daily basis.

As well as the location of the first arch bridge assessment carried out by Bill, Aberfeldy was also the site for the construction of the UK’s first ‘plastic’ cable-stayed footbridge, Linksleader Bridge, in 1992. Bill remembers taking a call from a university colleague, a member of the Aberfeldy Golf Club. The club wanted to add nine holes to their course but a river was in the way and use of an existing crossing was not allowed. Could Bill help? “It started life as a student design project through the year, and then Maunsell took over the design because obviously it had to be properly covered. The students signed up to build it in the summer.” The result was a cable-stayed bridge with spans of 25m, 63m and 25m, with 17m-high towers. The main elements were made in glass-reinforced plastic and the cables from Kevlar, with most materials being donated. It turned into a massive learning exercise on a number of levels. The deck panels were designed to slot together, but in order to interact with each other structurally they needed to be glued, which affected how they fitted together. Aluminium elements and tubes that had been originally been designed to link the cables and deck beams at different angles were delivered with the holes in the wrong place. During construction, the towers box sections under the deck were designed with a groove on three sides, so that a cross beam under the deck could be supported. “But the people who built them thought it would look prettier if it was flat, so they turned the thing round… And all sorts of stuff like that fascinated me and the site workers. To get lessons like that before you actually get to work…wonderful!”

Construction of Linksleader Bridge, the UK's first plastic footbridge, was a summer project carried out with Dundee University students

Although an exceptional project, the bridge took its toll at a time when Bill had just been made head of department. “I was spending mornings in Dundee University, doing department management stuff, and leaving at midday, driving to town to buy things for the site, then driving to Aberfeldy. And most nights I was there until 10:00pm before returning to Dundee. It took a bit out of my life.”

Not in keeping with his uncle’s injunction, Bill has clearly – and repeatedly – got his hands dirty, going so far as designing many a measuring system and related equipment during his efforts to understand arch bridges. This started in the 1970s, when dissatisfied with the expense of the monitoring equipment on offer he developed his own measuring devices that could take synchronous measurements over large patterns. His first kit consisted of a logger and 30 gauges using potentiometers. A colleague wrote a computer program that would fit a Fourier curve to the wave for each gauge, so all the data could be sampled and the deflections noted.

Moiré tell tales were initially developed by Bill for Leeds City Station

This fascination with measuring equipment continued after he retired from academia and founded Bill Harvey Associates in 2000. A year later, to measure movement at the vaults of Leeds City Station, he developed Moiré tell tales. These comprise small concentric patterns on cellophane, which when overlapped can measure about 0.2 of a millimetre of movement. “I was in Leeds City Station two years after their installation. I could still see the pattern from 6m away and thought that had a lot of leverage, so we started to manufacture and sell them.”

Temperature was found to be a factor behind the state of the Cleddau Bridge's bearings (Shutterstock)

One of the most memorable projects of his consultancy career arose in 2008, when he was asked to assess the pair of large linear roller bearings located at the end of the main span of Cleddau Bridge. This 820m-long steel box girder bridge in Wales had hit the headlines in 1970 with the collapse of a girder during construction, the last major bridge collapse in the country.

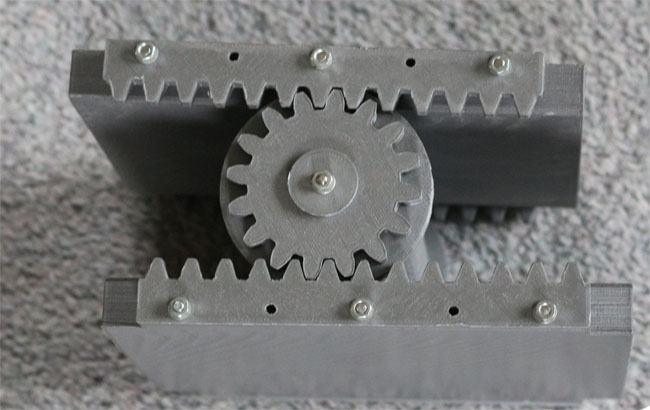

Cleddau Bridge instrumented linear roller bearings

The bearings were in a “mess”, not moving properly, and the bridge manager was aware that if the bearings became stuck, a lot of compression would be generated in a deck not designed to take it. A “fairly simple” monitoring system was designed and fitted by Bill Harvey Associates consisting of just six gauges. “The hard part of course, 15 years ago, was reading the data, storing it and transmitting it over the web.” His son Hamish, now involved in the consultancy, created a website and built the data logger to transmit the one-a-second measurements on an hourly basis. Meanwhile, Bill commissioned a fabricator to build four gauges to fit the rollers. Their clever design consisted of a cone that could be fixed by a ring of magnets directly over the centre of the bearing, where it was turned. “We then had a 300mm transducer fastened to the diaphragm on the bridge, so this rolls backwards and forwards, and we can tell exactly where the centre of the bearing is. One on each end of the bearing. And then two on the outer edge of the bridge measuring the whole bridge gap. Which is much easier with a draw wire potentiometer.”

From the top: Model of the Cleddau Bridge bearings and fabricated gauge to fit the bearings

The results of the thousands of measurements showed a 0.5mm differential across the width of the roller, which effectively caused a twisting action whilst bearing 400t. A significant factor in the roller bearings’ defective state turned out to be temperature. “Because the bridge runs north to south, when the sun came up in the morning the web heats up and bends in that direction. When it goes down in the evening, it heats up in the other. That bend was enough.”

Bill met the designer of the bridge, Walter Brown, to talk about the issue: “I said, ‘Did you think about that when you designed the bridge, that it bends sideways when the sun comes out?’ The answer was no…”

Today, Bill has a bee in his bonnet that has been nagging him for many years. He suspects that arch bridge behaviour is still not understood, and he sees evidence for this in countless multi-span rail viaducts in the UK. “The underlying thing is that the arch is not the bridge.” His epiphany came ten years ago, whilst looking at photographs of the damaged London Road Viaduct in the city of Brighton, which had been struck by a bomb in 1943. The bomb demolished a pier and two-thirds of two spans, with an improbable cantilever left on each side. “The whole story is there, in that picture. I had those pictures for 15 years before realising the connection with what is going on in [today’s] viaducts.” He is referring to the effect of concrete placed in the V-sections between viaduct arches. “So the arch sticks to it, it doesn’t flex in the way that is necessary for the normal behaviour we expect. And effectively what you’ve built is a Forth Bridge, a cantilever bridge with a little suspended span. And that was fine while all the vehicles were two axles, 4m apart. But in the 90s the 50t bogies got changed for 100t, four-axle wagons. So you put 100t on one span but nothing on the spans either side.” The result, he thinks, is an articulation of the arch at the top of that block, which is evidenced by horizontal cracks on the spandrel wall. “People say we’ll just pub a slab over the top and that will distribute the load better. Well, no, it won’t make any difference. It will perhaps reduce deflection by one or two percent.”

Bill suspects that this is what led to an 80m-long spandrel wall coming off a viaduct in Nine Elms, London in 2020. “A major thing for me is that the whole wall didn’t come off. There are long stretches where the wall has split down the middle, and it is the outside that has come off. The inside has stayed where it is. So it’s not pressure from behind that has thrown it off. It’s something else.” The walls underneath the spandrel, he suggests, have supported the spandrel while a rocking effect under the deck has guillotined the edge of the bridge.

To confirm his suspicions Bill has been calling for research into rail viaducts for over ten years as he fears the consequences of concrete sections failing off. One such project was developed and indeed did start last year. However, due to the high cost of designing and building of the measuring equipment, the project was financially “a complete disaster” for the consultancy. “It came to a stop earlier this year. We were told that for more funding they would have to go to tender. With my IP!”

Bill admits that he worries a lot about viaduct behaviour and competence in inspections. “If we accept that we don’t understand these things, then repetition is no good. You need to be thinking about what you’re looking at.” Time and time again he sees inspections being regarded as increasing costs that need to be minimised, but he believes that a different approach would pay dividends.

As an example, he highlights an international research project organised by the International Union of Railways. As part of the aim of consolidating current knowledge and making it available in codes, Bill was tasked with producing a guide to assessment. During the contract, he photographed the rail viaducts on the Glasgow South Western Line in Scotland when he noticed something. “I looked at these extended parapet walls where 300-1,000mm of additional ballast had been placed and at viaducts where the parapets hadn’t been extended. The ones where they had been extended were fine, but the ones where they hadn’t were in a state. That sort of overview is the sort of thing you only get if you see it like that. And nobody is doing that overview.”

As the interview comes to an end, I continue wondering about the seriousness of the consequences if Bill’s suspicions are correct. I also wonder whether anyone else alive could be better suited to this investigatory role, but I can’t.