The bridge has been set up at the Floriade international horticulture exhibition in Almere, which opened this month and will run until October.

Flax has long been used in the form of clothing, sacks and ropes but its potential as a construction material is now being examined through an EU research project. It is combined with a special bio-resin to create a light and highly stable material with properties comparable to aluminium or steel.

The EU project, Smart Circular Bridge, is using the new bio-composite to develop three bridges. The first Smart Circular Bridge has a span of 15m. It is the result of work by an international consortium of 15 partners led by Eindhoven University of Technology in the Netherlands. The project team consists of five universities, seven companies and three municipalities.

The EU project, Smart Circular Bridge, is using the new bio-composite to develop three bridges. The first Smart Circular Bridge has a span of 15m. It is the result of work by an international consortium of 15 partners led by Eindhoven University of Technology in the Netherlands. The project team consists of five universities, seven companies and three municipalities.

Two more of the bridges for pedestrians and cyclists will be built in Ulm in Germany and Bergen op Zoom in Netherlands later in 2022 and in 2023 respectively.

The resin comes from come from non-fossil sources as much as possible. The proportion of bio-resin is 25% for the first bridge, but it will reach 60% or more for the next bridges. This is achieved by using waste products from bio-diesel production and recycled PET bottles.

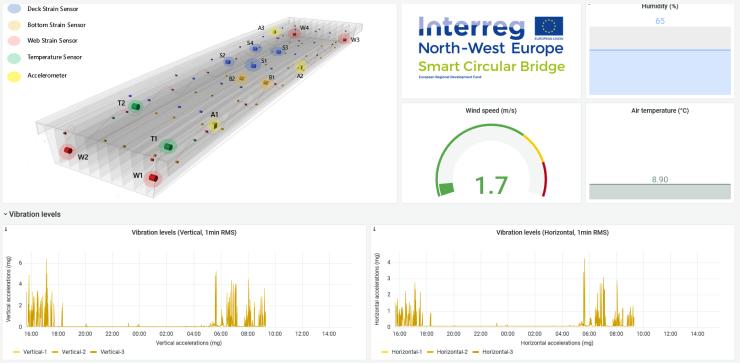

As bio-composites offer great opportunities, research on the materials is continuously ongoing, said the development team. Almost 100 sensors in the bridge provide data on the behaviour of the materials in everyday use. The research will seek to answer questions about how the structure behaves when, say, 200 people walk over it at the same time, what happens in different weather conditions and how the materials age.

A structural health monitoring system with optical glass fibre sensors in the bridge provide information on material strains, and acceleration sensors detect even the finest vibrations caused by wind.

Evaluation of data from the sensors is carried out with the help of artificial intelligence (AI) to recognise patterns in material behaviour. The data can be viewed by anyone on a dashboard on the project’s website.

At the same time, engineers will be using the data to refine their calculation and material models with this data. On this basis, they will further develop materials and design models for the next bridges and many other applications, said the project team. Currently, teams are already researching columns and façade elements.

With the circular economy in mind, the project is investigating which options are open for the building material after the bridges have reached the end of their life after many decades. Currently, three possibilities are conceivable: mechanical, chemical, and even biological recycling with fungi. It is important that the material’s usage cascade lasts as long as possible, said the team. To achieve this, the end-of-life options have to be taken into account right from the start of project.

“These materials have a great future,” said project leader Professor Rijk Blok from TU Eindhoven. “In particular, the intensive cooperation between science, industry, and communities has given a big push to materials development”.

“The current results make us optimistic: we expect to build bridges with significantly larger spans and higher loads in the future,” added Professor Dr Patrick Teuffel from TU Eindhoven, the lead partner in the international Smart Circular Bridge consortium.