Research ahead of an anti-corrosion project on a bridge in New Zealand saw a model buffeted by extreme weather in a wind tunnel.

Auckland System Management Alliance will be carrying out anti-corrosion work on the city’s Harbour Bridge. To avoid polluting the river with flakes of paint, they will install an enclosed scaffold beneath the bridge. But during the planning, questions arose about the effect of extreme weather on the bridge while it was loaded with the scaffold.

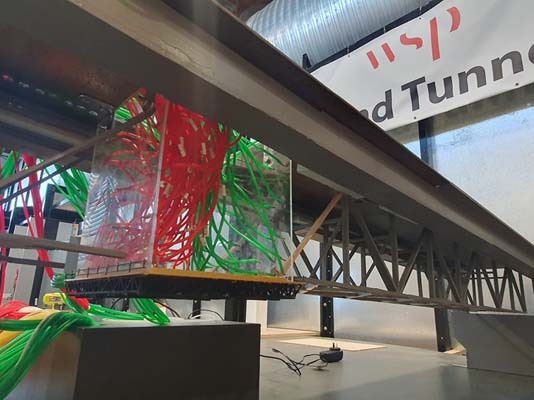

Structural engineering consultants Beca built a 1:100 scale model of the bridge and the scaffold using 3d printed parts and set it up in WSP’s wind tunnel in Wellington.

WSP principal research engineer Nick Locke said, ‘“We were interested in the maximum loads the hanging structure could be subjected to, which was about 46 metres a second at 40 metres above the ground. That's the wind speed you'd expect to occur in a once in 2,500-year storm, which is a scenario well above the wind speed threshold at which the bridge would be closed to traffic.”

The 3D printed bridge model in the WSP wind tunnel. Credit: WSP

The team also ran a study to understand wind flows around the scaffold. This showed that air flowing beneath it created suction that pulled down on the bridge, increasing its gravity loading.

“Wind tunnel testing was crucial for this project because it helped the engineers understand exactly how wind would interact with the scaffold and the bridge,” said Nick.